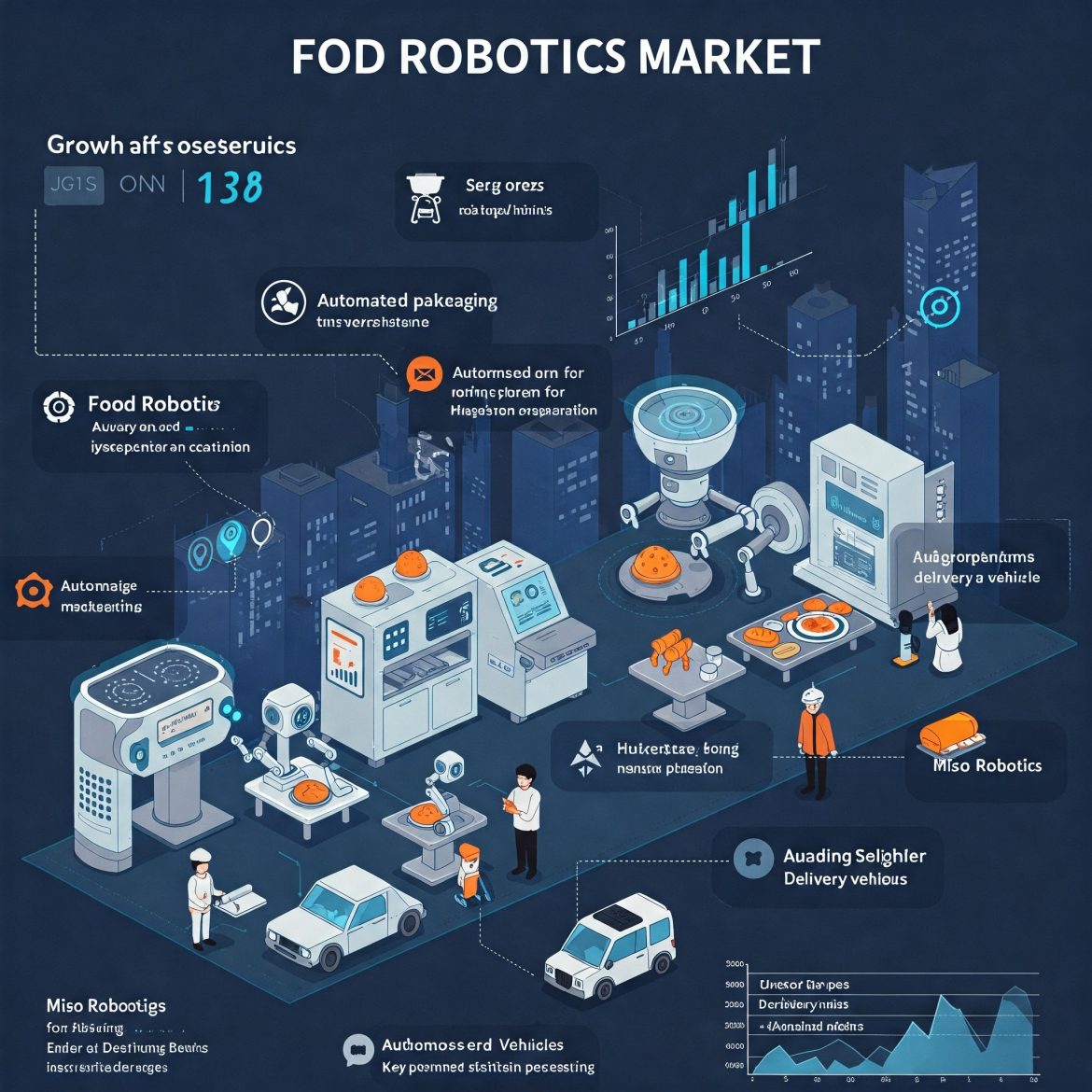

The size of the global food robotics market was US$ 3.1 billion in 2024. Going forward, the market is expected to reach US$ 7.9 billion in 2035 at a growth rate (CAGR) of 10.01% during 2023-2032. The market is growing at a robust pace based on the shortages of labor, technological developments, growing food processing demand, imposition of regulatory requirements for ensuring food safety, and increasing consumers’ expectations for food quality and variety.

Food Robotics Market Analysis:

Market Size and Growth: The market is experiencing steady growth due to growing automation in the food sector, changing technology capabilities, and increased use of robotics to improve efficiency and productivity.

Key Market Drivers: Some of the major drivers for the market growth are labor shortages, increasing labor costs, increasing demand for processed food, tough food safety regulations, and the continued drive for efficiency, consistency, and quality in food manufacturing.

Technological Developments: New breakthroughs in artificial intelligence (AI), machine learning (ML), and sensor technologies are transforming food robotics, which can now carry out more advanced tasks with greater accuracy. Also, the growth of collaborative robots (cobots) that cooperate with humans is aiding the growth of the market.

Industry Usage: The industry is witnessing a high demand for products in packaging, repackaging, palletizing, picking, and processing, to enhance speed, precision, and hygiene.

Major Market Trends: The major market trends include the continuous trend of utilizing flexible, multi-functional robots that can execute multiple tasks. Also, the rising emphasis on robots which can guarantee food safety and regulatory compliance is boosting the market growth.

Geographical Trends: Europe drives the market through its leading-edge technological infrastructure, the cost of labor, and enforcement of stringent food safety standards. Other geographies are also witnessing tremendous growth, driven by technology adoption and shifting consumption patterns.

Competitive Landscape: It is marked by the aggressive participation of major players that are undertaking strategic alliances, R&D initiatives, and venturing into emerging markets. In addition, firms are emphasizing innovation and diversifying their product line to target varied food industry segments.

Challenges and Opportunities: The market is confronted with several challenges, including high upfront investment expenses and the requirement of skilled operators to run and service robotic systems. Nevertheless, advancements in affordable and easy-to-use robots and their quick uptake to address the changing needs of the food industry are opening up new opportunities for the growth of the market.

Companies Mentioned

- ABB Ltd

- Bastian Solutions LLC (Toyota Industries Corporation)

- Denso Corporation

- Fanuc Corporation

- Kawasaki Heavy Industries Ltd.

- Kuka AG (Midea Group Co. Ltd.)

- Mitsubishi Electric Corporation

- Rockwell Automation Inc.

- Seiko Epson Corporation

- Stäubli International AG

- Universal Robots A/S (Teradyne Inc.)

- Yaskawa Electric Corporation

- Others

Food Robotics Industry Segmentation

Breakup by Type:

SCARA

Articulated

Parallel

Cylindrical

Others

Articulated food robotics dominate the market share.

Breakup by Payload:

Low

Medium

Heavy

Medium payload has the largest market share in the industry.

Breakup by Application:

Packaging

Repackaging

Palletizing

Picking

Processing

Others

Recent technological innovations

Technological innovation in robotics, artificial intelligence (AI), and machine learning (ML) is taking center stage in revolutionizing the ability of food robots. Contemporary robotics are equipped with sophisticated sensors, vision systems, and AI algorithms that can accomplish intricate tasks with high accuracy and flexibility. Additionally, they are able to learn and enhance their work over time, with increased efficiency and effectiveness. Also, the use of vision systems makes robots capable of recognizing, sorting, and processing various food products and adjusting to changes in size, shape, and color.

Apart from this, the advent of collaborative robots that are capable of performing work collaboratively with human employees, bringing flexibility and more efficiency to the production line, is having a beneficial impact on the market growth. Additionally, they can be reprogrammed and redeployed for various tasks easily, thus highly versatile in catering to changing needs of the production.

The growth in the demand for processed foods

The growing need for packaged and processed food, driven by shifting consumer preference towards convenience foods being RTE or easy to prepare, is driving the market growth. Processed food demands standardized quality, safety, and hygiene standards, which may be difficult to obtain through manual interventions. According to this, food robotics provides precision and consistency, which are necessary to sustain the product quality and consumer expectations. In addition, computerized systems can process enormous quantities of food items economically with uniformity of size, shape, and package, which is paramount for branding. Robotics also facilitates quick capacity scaling to meet varying market requirements without a sacrifice in quality.

The imposition of stringent food safety regulations

The imposition of tight food safety rules to provide for the safety and quality of foods is driving the market expansion. According to this, robotics is also crucial in fulfilling different regulatory requirements since they mechanize operations, which helps in minimizing the risk of contamination caused by humans. In addition, robots can process food products in a controlled environment, reducing human contact and therefore the risk of contamination by pathogens, allergens, or foreign bodies. Further, they provide uniformity in handling and processing of food, which is important to ensure quality standards. Further, food robotics provide traceability and data logging functionalities, which assist in compliance by maintaining accurate records of the manufacturing process.

The increasing consumer demand for quality and variety

The increasing consumer demands for food quality and assortment are driving the market growth. Consumers are increasingly becoming informed and sophisticated, looking for high-quality products with great variety. The use of robotics in the food industry allows manufacturers to capitalize on these expectations by offering the ability to produce a great variety of high-quality items at an efficient level.

Email us NOW to buy this an EXCLUISVE REPORT with very important DATA-